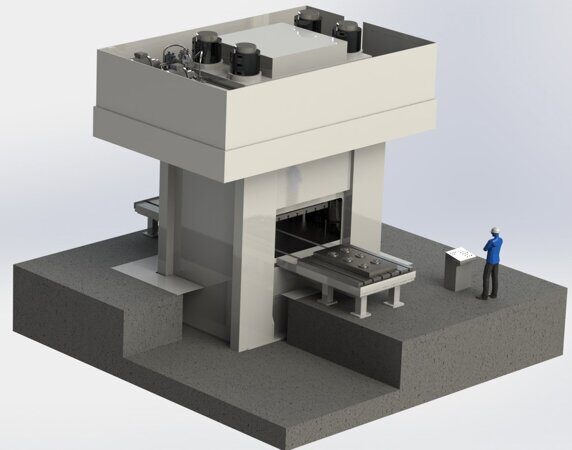

Hydroforming presses

CNC hydroforming presses of Gefest-H.06 series are designed for hydraulic molding of parts of complex spatial shape from steel, non-ferrous alloys and titanium by pressing with a hydroelastic medium.

The sheet metal takes the form of a solid one-sided matrix under the action of an elastic rubber diaphragm, on the surface of which pressure is exerted by a working fluid (castor oil). High accuracy of matching the shape of the matrix is achieved due to hydrostatic compression of the sheet, in the same at all points of the surface and does not depend on the shape of the surface.

Industry areas

Used in advanced mechanical engineering, aircraft manufacturing, spacecraft production, defense industry, prototypes production and production of complex parts in small-scale production.

Peculiarities

- Column composite frame

- Hydraulic components Hawe, Bosch-Rexroth

- Electrical components Siemens, Schneider Electric, Omron

- Made in Europe or USA membrane

- Open software TM Gidropress

Standart equipment

- Two loading tables

- Water oil cooler

- OMRON controller with LCD display

- Remote control panel

- Laser work area protection system

- Manual and automatic operating modes

Options

- Drawling into a polyurethane matrix

- High performance hydraulic system

- Recycling water supply system with water softening

Advantages of hydroforming compared to traditional drawing

- No scratches on the surface of the part. No finishing maching required.

- Small tolerances on parts relative to the matrix due to high hydrostatic pressure.

- Possibility of cutting parts directly during the pressing process.

- Low cost of the dies, short production time.

- Manufacturing of parts with complex shapes, including cutouts and bending of edges.

- Reducing preparation time for production and easy modification of the matrix when making changes to the product design

| Characteristic | GEFEST 2000H.06 |

GEFEST 3000H.06 |

GEFEST 5000H.06 |

GEFEST 10000H.06 |

GEFEST 15000H.06 |

GEFEST 22000H.06 |

|---|---|---|---|---|---|---|

| Hydroforming force, tons | 2000 | 3000 | 5000 | 10000 | 15000 | 22000 |

| Hydroforming pressure, Mpa | 60 | 60 | 60 | 60 | 60 | 60 |

| Workpiece dimensions (length×width or diameter), mm | Ø700 | Ø800 | Ø1000 | 2000×1000 1400×1400 |

2500×1200 1700×1700 |

3000×1500 |

| Open height, mm | 350 | 350 | 400 | 500 | 700 | 700 |

| Drawing depth, mm | 250 | 250 | 250 | 300 | 320 | 350 |

| Cycle Time, sec | 180 | 180 | 200 | 220 | 230 | 300 |

| Main power, kW | 90 | 120 | 220 | 250 | 300 | 350 |

| Weight(approx), tons | 120 | 150 | 210 | 340 | 420 | 590 |

| Price, USD |